Detectamet's Fully Detectable Pen Refills

Detectamet's long established reputation of detectable innovation is consistanly providing food and pharmaceutical producers with a way to push towards complete control of open product areas, with the goal of eliminating contamination by foreign bodies.

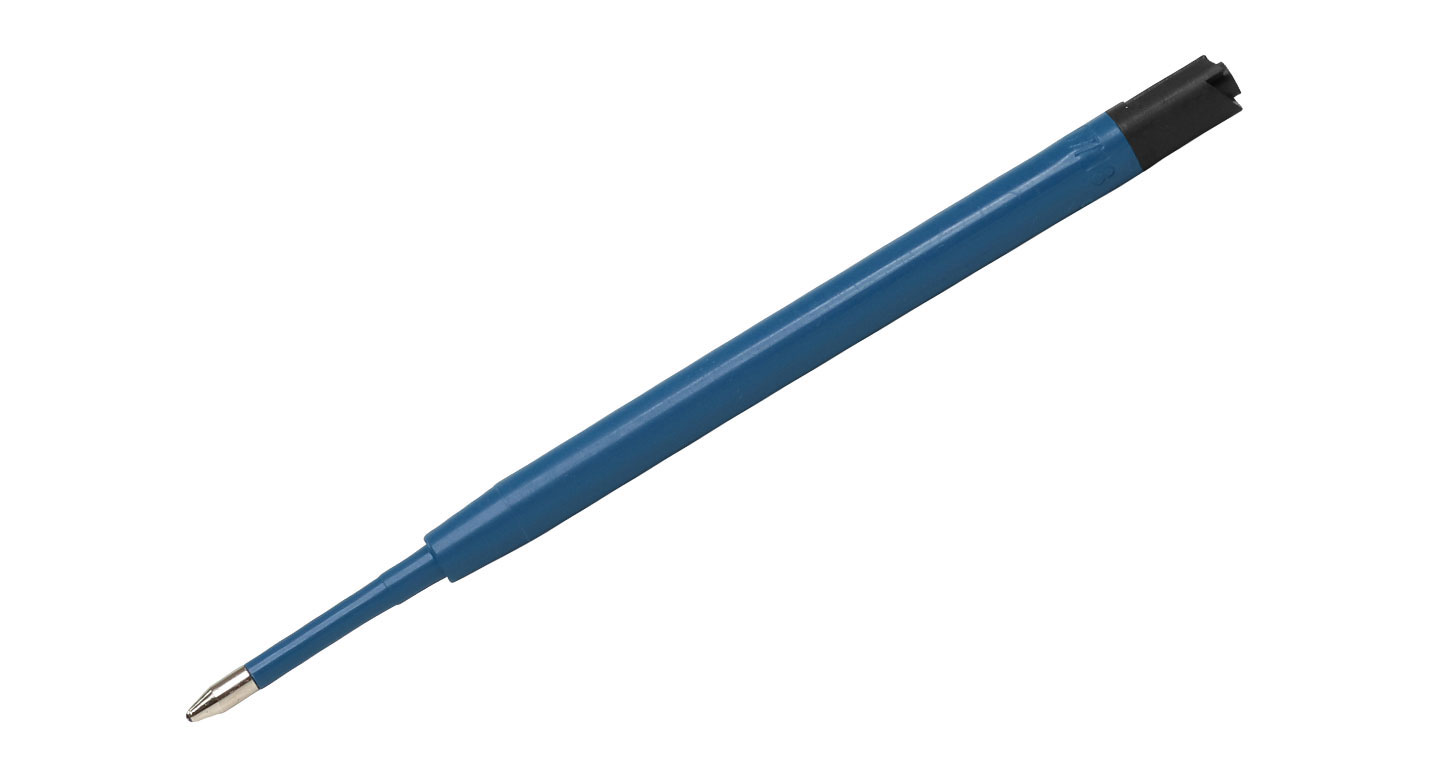

The latest new development is the introduction of the patent pending fully detectable ink refill which is now being incorporated exclusively into Detectamet's range of Metal Detectable Pens.

The complete ink cartridge, both the body and the end stop, are now made from our proven Metal Detectable and X-Ray Visible Plastic. This makes the whole of the pen detectable by foreign-body detection equipment by eliminating the end stop which is commonly made from non-detectable plastic.

With the introduction of thefully detectable plastic ink refill, Detectamet's range of detectable pens are the only pens available that can claim to be fully detectable by foreign-body detection equipment.

Why Choose The BRC Global Standard For Food Safety?

The BRC Global Standard for Food Safety is the number one global market leading GFSI scheme. Supply chain resilience and transparency can be achieved using the Food Safety Standard and reported on the BRC Global Standards Directory, which in turn increases customer confidence in your brand.

- Protects your brand and consumer

- Reduce waste, complaints, recalls and rejected products

- Ensure your customers maintain confidence in your food safety programme and supply chain management

- Accepted and specified by many retailers, manufacturers, ingredients companies, food service organisations and raw material processors worldwide as part of their supplier approval process

- First Standard to be GFSI benchmarked

BRC Global Standard For Food Safety Issue 8

The information to develop Issue 8 of the BRC standard has been reviewed by working groups made up of international stakeholders representing food manufacturers, retailers, food service companies, certification bodies and independent technical experts.

The focus has been on:

- Encouraging development of product safety culture

- Adding clarity to the requirements for high-risk, high-care and ambient high-care production risk zones

- Providing greater clarity for sites manufacturing pet food

- Ensuring global applicability and bench-marking to the Global Food Safety Initiative (GFSI)

Detectamet UK (English - £ GBP ) Click here to change your currency, region and language.

Detectamet UK (English - £ GBP ) Click here to change your currency, region and language.