10 Essential Food Safety Tips to Prevent Recalls with Metal Detectable Gloves

Here at Detectamet, we are deeply committed to ensuring the utmost food safety. As we like to say: food safe is food smart.

Of course, navigating the complex maze of rules and regulations can be daunting, especially when each food processing operation has unique processes and challenges of its own.

Recognising this, we've dedicated ourselves to developing practical, innovative solutions tailored to these diverse needs. Food safety in the food processing industry is not just a requirement; it's a responsibility. A single lapse can lead to expensive recalls, significant harm to a brand’s reputation and an erosion of customer trust.

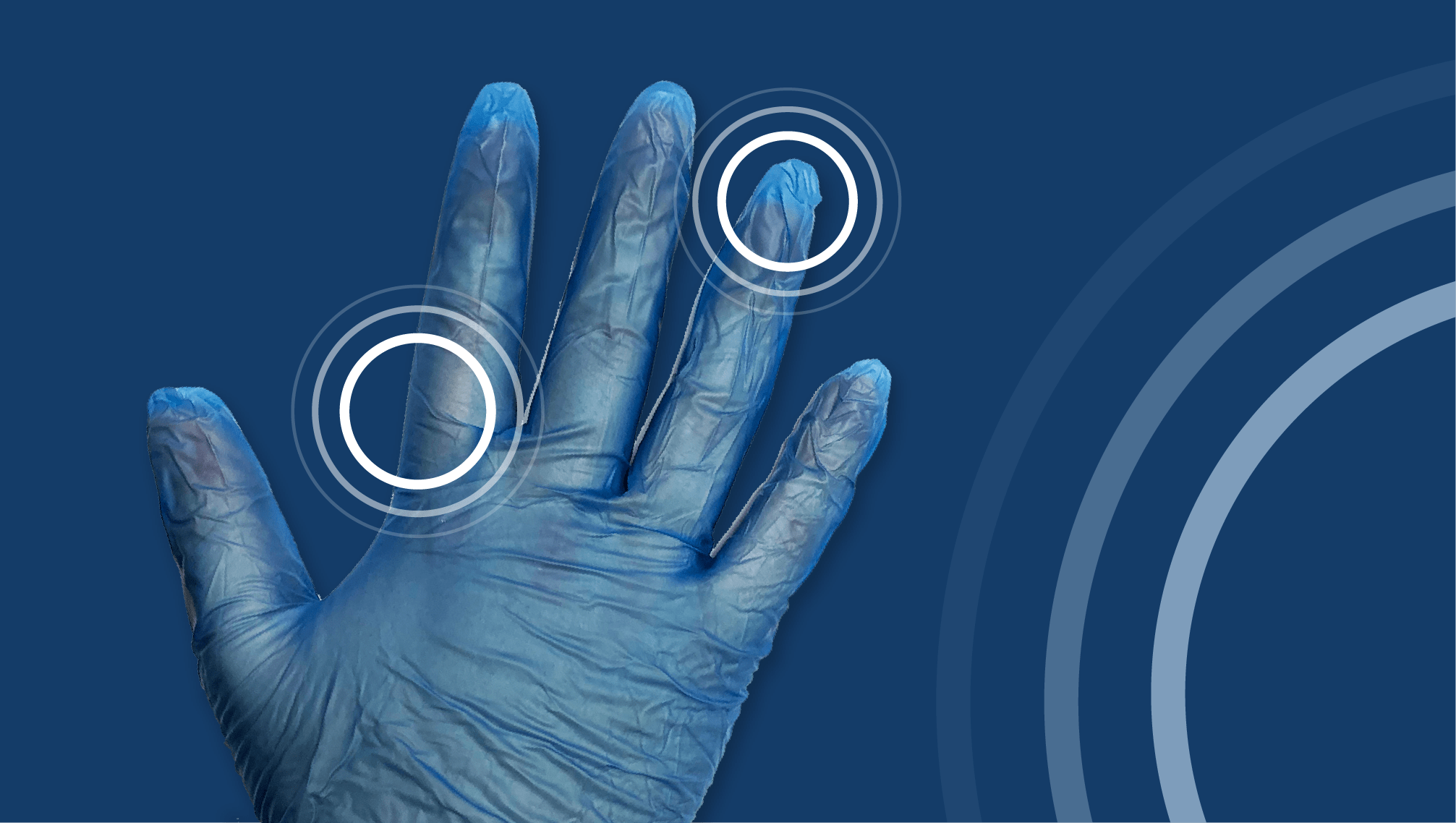

In this high-stakes environment, metal detectable gloves from Detectamet have emerged as a revolutionary solution, offering an added layer of protection and peace of mind. To assist you in enhancing your food safety protocols, we've compiled ten essential (finger) tips.

They are part of our comprehensive strategy to safeguard your products, your customers and your brand's integrity.

Read on to discover how these metal detectable gloves can be a cornerstone of your food safety strategy and fit your business… like a glove.

Table of Contents

- Table of contents:

- 1) Enhanced Detectability

- 2) Compliance With Regulations

- 3) Reduce Contamination Risks

- 4) Quality Assurance

- 5) Employee Safety

- 6) Improved Hygiene Practices

- 7) Tracability In Production Lines

- 8) Customer Trust

- 9) Cost-Effective Solution

- 10) Peace of Mind

- Detectamet’s Metal Detectable Glove Range

- Food Takeaways

1) Enhanced Detectability

Challenge: What if fragments of gloves contaminate your food products during processing?

Solution: Detectamet's metal detectable gloves are the answer. Specially engineered for high visibility in metal detection systems, they ensure that any detached piece can be promptly identified and removed. This crucial feature significantly diminishes the risk of contamination, safeguarding the quality and safety of your food products.

2) Compliance With Regulations

Challenge: What are the implications for your food production line if regulatory compliance fails due to contamination?

Solution: In the event of regulatory non-compliance, the risks extend beyond immediate product safety concerns. There can be legal ramifications, costly recalls and damage to brand reputation.

Detectamet's metal detectable gloves serve as a hands-on critical line of defence. Their design for high visibility in detection systems means that any glove fragment, if present, can be quickly identified and removed. This not only prevents potential contamination passing on through your production pipeline, but also plays a pivotal role in ensuring that your production line adheres to strict industry regulations.

3) Reduce Contamination Risks

Challenge: How can you ensure your food processing operation consistently meets the ever-evolving food safety standards?

Solution: Embrace Detectamet’s gloves as a vital component of your compliance toolkit. These gloves aren't just about protecting products; they're about aligning your operations with rigorous food safety standards.

By incorporating our gloves into your daily food processes, you're taking a proactive step in maintaining compliance with industry regulations. This commitment to compliance not only keeps your operations reputable but also fortifies your standing as a responsible and reliable entity in the food processing industry.

4) Quality Assurance

Challenge: In the high stakes of food processing, how can you ensure that every product reflects your commitment to quality?

Solution: Turn to Detectamet’s gloves, crafted from durable and high-quality materials. These gloves aren’t just protective gear; they are a testament to your dedication to quality assurance. Their reliability and consistency are integral in maintaining the high standards of your food processing operations. Plus, your team will (g)love them.

5) Employee Safety

Challenge: How do you ensure the safety of your employees while they handle various tasks in food processing environments?

Solution: Detectamet's gloves aren't just tools for maintaining food safety; they're essential for employee protection. They can shield your staff from potential hazards, thereby maintaining a safer and more secure work environment.

When your team is equipped with Detectamet gloves, they're not just wearing safety gear; they're an integral part of a culture of care and protection that permeates every part of your operation.

6) Improved Hygiene Practices

Challenge: In an industry where hygiene is paramount, how can you ensure that your practices are consistently top-notch?

Solution: Detectamet's metal detectable gloves are pivotal in this regard. By integrating these gloves into your daily operations, you're not just equipping your staff with safety gear – you're actively promoting a culture of heightened hygiene.

You’ve got to hand it to them - these gloves prevent direct skin contact with food, drastically reducing the risk of cross-contamination.

7) Tracability In Production Lines

Challenge: How do you manage the challenge of traceability in the complex environment of a food production line?

Solution: Detectamet's gloves offer a solution with their inherent traceability. The smallest piece of these gloves, if separated, can be detected through metal and X-ray detection systems.

This capability ensures that every part of your production line is monitored for safety, maintaining the integrity and trust in your processing chain.

8) Customer Trust

Challenge: How can you reinforce customer confidence in your food safety measures?

Solution: By integrating Detectamet gloves into your operations, you're sending a clear message about your commitment to safety.

This proactive approach to preventing contamination not only enhances product safety and reduces the danger of costly recalls, but also strengthens customer trust, as they recognise your dedication to their well-being.

9) Cost-Effective Solution

Challenge: What's an effective strategy to avoid the high costs associated with product recalls?

Solution: Investing in Detectamet gloves is a cost-effective strategy. By preventing contamination and the potential for product recalls, these gloves help avoid the expenses and brand-damage associated with such events.

Detectamet's super cost-effective metal detectable gloves safeguard your financial stability and brand integrity.

10) Peace of Mind

Challenge: In the demanding and high-responsibility realm of food processing, how do you achieve peace of mind?

Solution: Detectamet gloves offer that much-needed peace of mind. Their reliability in preventing contamination means you can focus on your core operations, confident in the knowledge that your safety measures are robust and effective.

Detectamet’s Metal Detectable Glove Range

Detectamet offers a range of metal detectable gloves suitable for various food processing needs. Here are a few products popular among food processors.

Metal Detectable Nitrile Gloves

Part of the Detectamet Detectaglove range, our SOFHT award-winning disposable blue metal detectable nitrile gloves are perfect for use within a food manufacturing or processing environment. Offering great strength and durability and manufactured from 100% nitrile, these food industry gloves are latex and powder free and suitable for food handling.

Available in 3 sizes: Medium, Large & X-Large.

Blue Metal Detectable Disposable Vinyl Gloves

Detectamet’s patented blue metal detectable disposable food-safe gloves are powder free and manufactured from food safe latex-free vinyl.

Available in 3 sizes: Medium, Large & X-Large.

Metal Detectable Natural Rubber Gloves

These reusable powder-free rubber gloves are manufactured from food-safe material and suitable for use with acidic & fatty foods.

Available in five sizes.

Food Takeaways

Implementing metal detectable gloves in your food processing operations is a straightforward yet cost-effective step towards ensuring food safety and preventing recalls. Here’s some quick takeaways to keep in mind:

Enhanced Detectability: Quick identification and removal of detached glove pieces to reduce contamination risk.

Compliance with Regulations: Adherence to food safety standards and industry regulations.

Reduce Contamination Risks: Prevention of direct hand contact with food.

Quality Assurance: High-quality, durable materials ensuring reliability in food processing.

Employee Safety: Protection against potential hazards in the workplace.

Improved Hygiene Practices: Promotion of heightened hygiene and prevention of cross-contamination.

Traceability in Production Lines: Ensuring safety and integrity in the food processing chain.

Customer Trust: Strengthening consumer confidence in food safety measures.

Cost-Effective Solution: Avoiding expense and brand damage associated with product recalls.

Peace of Mind: Confidence in robust and effective safety measures.

Visit our website to explore our full range of Detectamet metal detectable and x-ray products and find the perfect solution for your needs.

Detectamet UK (English - £ GBP ) Click here to change your currency, region and language.

Detectamet UK (English - £ GBP ) Click here to change your currency, region and language.